Polymers

Introduction Structure

Liposomes are drug delivery carriers known for their excellent biocompatibility. However, traditional liposomes suffer from issues such as instability and short half-lives. Addressing these issues, polymer modification of liposomes has proven to be an effective solution. Creative Biolabs has been dedicated to the development of lipid-based delivery systems, including liposomes. Our polymer-modified liposome development services can enhance both the colloidal and in vivo stabilities of liposomes, thereby addressing various challenges in drug delivery.

Introduction of Polymer-Modified Liposomes

Polymers exhibit greater stability than lipids and are less susceptible to oxidative degradation. Their properties can be extensively tailored across a broad range by adjusting their molecular weight. The modification of liposomes with polymers retains the advantages of liposomes as drug delivery carriers while overcoming their limitations and imparting specific functions or properties to liposomes.

-

Enhanced stability: Minimizes the leakage of the payload, enhancing drug bioavailability.

-

Modulating drug release profile: Adjusts the rigidity of the liposomal membrane to control the drug release rate.

-

Stealth properties: Prolongs the circulation half-life of liposomes in the bloodstream.

-

Mucoadhesive properties: Increases the residence time of drugs.

Stimuli-responsive properties: Under specific conditions, the dissolution or conformational change of the polymer can induce the rupture of the lipid bilayer, facilitating drug release.

Structure of Polymer-Modified Liposomes

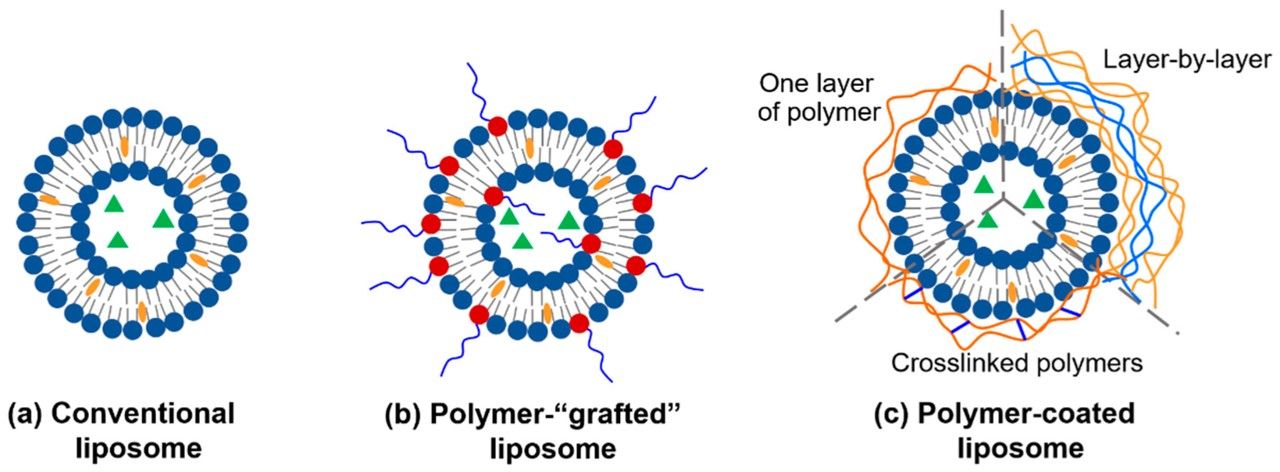

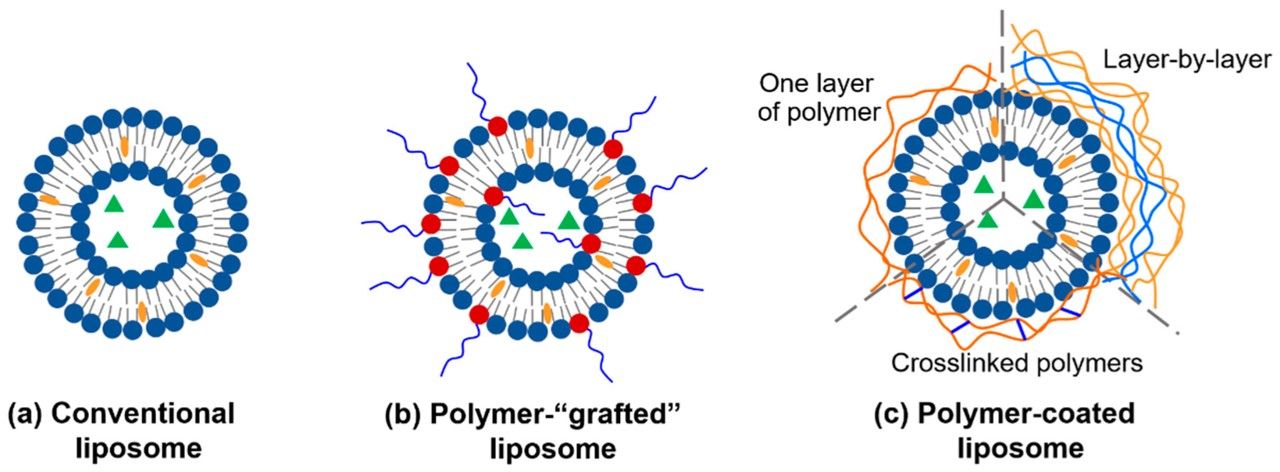

Polymer-modified liposomes can be prepared through two methods: grafting and coating, resulting in polymer-grafted liposomes and polymer-coated liposomes, respectively.

Fig.1 The structure of polymer-modified liposomes.1, 2

Fig.1 The structure of polymer-modified liposomes.1, 2

-

Polymer-Grafted Liposomes

Polymer-grafted liposomes are obtained by using "grafting" techniques to attach polymer chains to the surface of liposomes. Hydrophilic polymers create a thicker hydrated layer on the liposomal surface, inhibiting interactions both between liposomes and with proteins and/or cells in the biological environment. These interactions are influenced by the molecular weight, configuration, and grafting density of the polymers. Generally, increasing the molecular weight and grafting density of the polymers enhances the liposomes' half-life. Furthermore, the grafted polymers can take on "mushroom" or "brush" forms. Generally, a mushroom regime is observed with lower concentrations of grafted polymers, whereas higher concentrations lead to the formation of a brush regime.

Polymers can be adsorbed onto the surface of liposomes through nonspecific interactions such as electrostatic, hydrogen bonding, and van der Waals forces, which can enhance the physicochemical properties of the liposomes. This can be achieved through the following methods.

One Layer of Polymer

Dropping a polymer solution into pre-formed liposomes can result in the formation of liposomes coated by one polymer layer, with the configuration influenced by the polymer's structure, charge, and molecular weight. Typically, charged polymers can impart electrostatic repulsion to the liposomes, enhancing their colloidal stability.

Layer-by-Layer (LbL)

The LbL technique utilizes electrostatic attraction, hydrogen bonding, and other interactions as driving forces to deposit charged polymers onto the liposome surface, which facilitates the development of a stable coating layer. In comparison to liposomes coated with a single polymer layer, thin multilayered liposomes exhibit greater robustness.

Cross-Linked-Polymer-Caged

The chemical cross-linking of the polymers coating the liposomes can create polymer-caged liposomes, enhancing liposome stability by diminishing the polymer's propensity to dissociate.

As experts in liposome development, Creative Biolabs is dedicated to providing our clients with high-quality polymer-modified liposome development services. No matter the challenge you face, we can customize solutions to help you reach new heights in the field of polymer-modified liposomes.

References

-

Cao, Yifeng, Xinyan Dong, and Xuepeng Chen. "Polymer-modified liposomes for drug delivery: from fundamentals to applications." Pharmaceutics 14.4 (2022): 778.

-

Distributed under Open Access license CC BY 4.0, without modification.

For Research Use Only. Not For Clinical Use

Fig.1 The structure of polymer-modified liposomes.1, 2

Fig.1 The structure of polymer-modified liposomes.1, 2

For Research Use Only. Not For Clinical Use

For Research Use Only. Not For Clinical Use