Silica Nanoparticle Annotation

Silica nanoparticles are nanoscale carrier materials that are easy to prepare, separate and surface-modify, and have good biocompatibility, showing attractive applications in the field of drug delivery and controlled release. With extensive experience and broad expertise in nanoparticle preparation and development, Creative Biolabs can provide precisely the customized nanoparticle products you need.

Introduction of Silica Nanoparticles

Due to the microfabrication of particle size and the dramatic increase in specific surface area, silica nanoparticles have gained widespread applications and attention in drug delivery and biomedical fields in the last few years thanks to their unparalleled properties. Monodisperse non-porous silica (10 nm - 1.5 μm, 2.0 g/cm3) and porous silica particles (3 μm - 1.5 μm, 1.8 g/cm3) can be prepared by the Stöber method using silanol monomer as the basic raw material. Also, by adjusting the concentrations of NH4OH, H2O and ethylsilicate and other reaction conditions, silica nanoparticles with various particle size distributions can be prepared.

Properties of Silica Nanoparticles

Many characteristics of silica nanoparticles facilitate its application in drug delivery. First, the uniform and ordered surface pore size of porous silica allows for fine control of drug loading and release. Second, the high porosity provides sufficient drug loading, while the high surface area allows for effective adsorption and transport of drugs. In addition, silica nanoparticles have a density of up to 1.96 g/cm3 and can be separated from the suspension by centrifugation, which makes them easier to handle compared to polymeric particles of the same size. Finally, the surface hydrophilicity of silica nanoparticles makes them chemically stable and inert in a solvent environment, neither deforming nor dissolving.

Functionalized Modification of Silica Nanoparticles

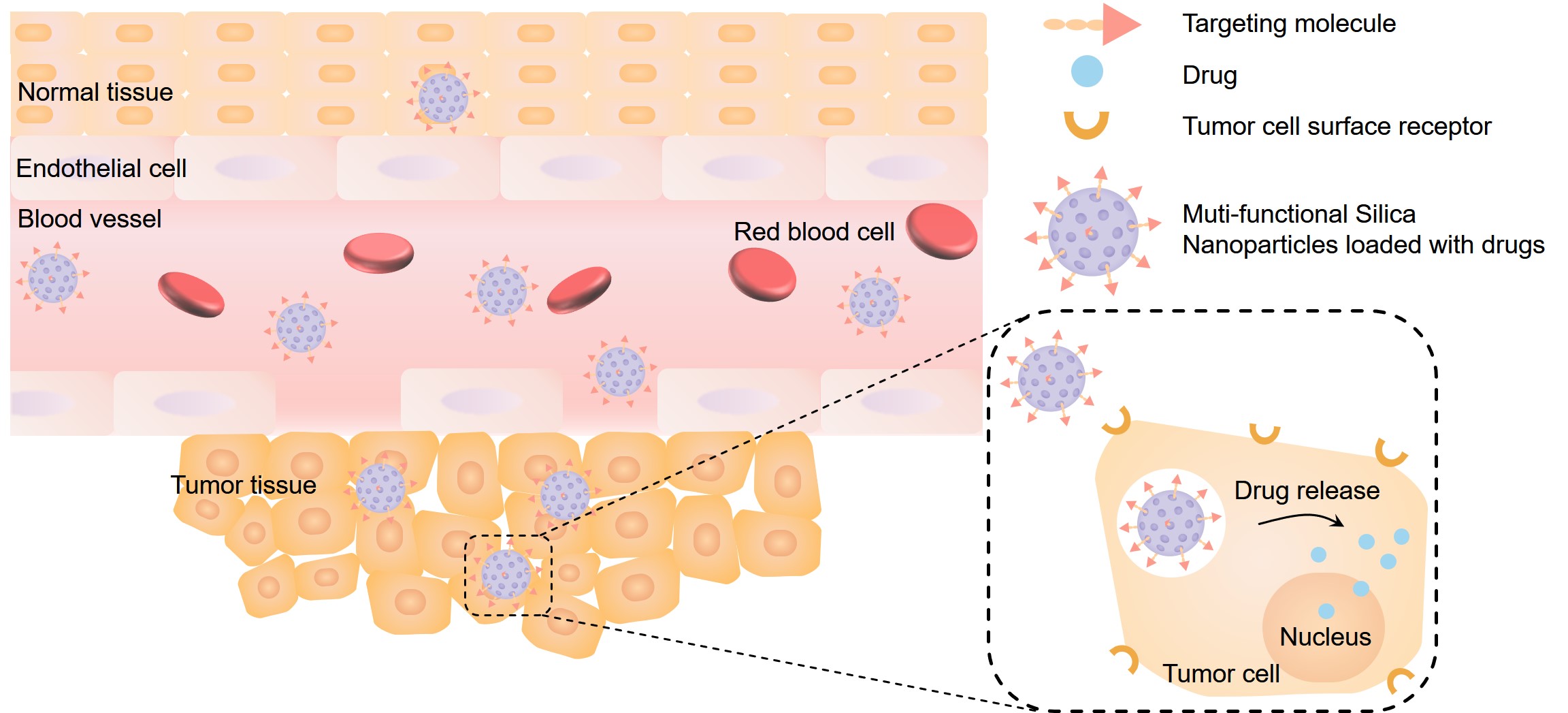

The presence of a large number of hydroxyl unsaturated residues makes the silica nanoparticles hydrophilic and lipophobic, with the risk of easy agglomeration. Functionalized modification of silica nanoparticles with reactive functional groups to regulate and control their surface activity can reduce their hydroxyl effect and hydrophilicity, which can not only improve and enhance interparticle dispersion and biocompatibility, but also endow nanoparticles with new functions such as stimulus responsiveness, thus achieving controlled and slow release of protein-nanoparticle conjugated platform and oligonucleotide-nanoparticle conjugated platform. Moreover, a variety of cleavable linkers and non-cleavable linkers are all available.

There are two functionalized modification pathways used for the surface modification of silica nanoparticles depending on whether the groups of the modified molecules react chemically with the hydroxyl groups or not. One is physical modification by adjusting the ratio of hydroxyl groups on the surface, and the other is chemical modification by changing the chemical properties.

- Physical modification is the deposition of coating substances onto the particle surface using surface deposition and physical effects such as adsorption, encapsulation and coating through hydrogen bonding, van der Waals forces and coordination, a process that does not involve chemical reactions of ionic or covalent bond formation.

- In contrast, chemical modification refers to the reaction of organic or inorganic molecules as functional group donors with hydroxyl groups containing unsaturated residues, including spontaneous coupling by silane coupling agents and nucleophilic interaction of groups such as amines or carboxylates, thereby immobilizing the ligands. In addition, the simultaneous modification of silica nanoparticles by a combination of physical and chemical modifications has led to both improved material dispersion stability and the preparation of a variety of silica nanoparticles with excellent properties.

Fig.1 In vivo process of an silica nanoparticles-based controlled and targeted drug delivery system.

Fig.1 In vivo process of an silica nanoparticles-based controlled and targeted drug delivery system.

Fluorescent Silica Nanoparticles

Fluorescent silica nanoparticles and quantum dot nanocrystals have similar fluorescence properties; however, fluorescent silica nanoparticles are less expensive to synthesize than quantum dot nanocrystals because they have standard organic dyes and do not rely on the fabrication of highly accurate diameter populations of reproducible semiconductor particles to tune the emission wavelength. Silica can capture dye molecules during Stöber process or produce hydrophilic particles using a reverse microemulsion process in which detergent micelles formed in a water-in-oil system form discrete nanodroplets, and water-soluble fluorescent dyes are encapsulated in silica nanoparticles upon incorporation. The fluorescent particles can also be coupled with biomolecules containing affinity ligands after formation, enabling functional surface modifications.

Fluorescent silica nanoparticles improve the photophysical properties such as photostability and fluorescence brightness of standard and commercially available organic dyes, and the silica-based particles are more hydrophilic and biocompatible than quantum dots. Thus, silica nanoparticles can further broaden their bioapplications by doping with suitable organic dyes or metal chelate luminescent molecules.

With the efforts of our professional technical team, Creative Biolabs has various types of nanoparticle product lines and we provide high quality customization of nanoparticles. If you are interested in silica nanoparticle products, please contact us for more information.