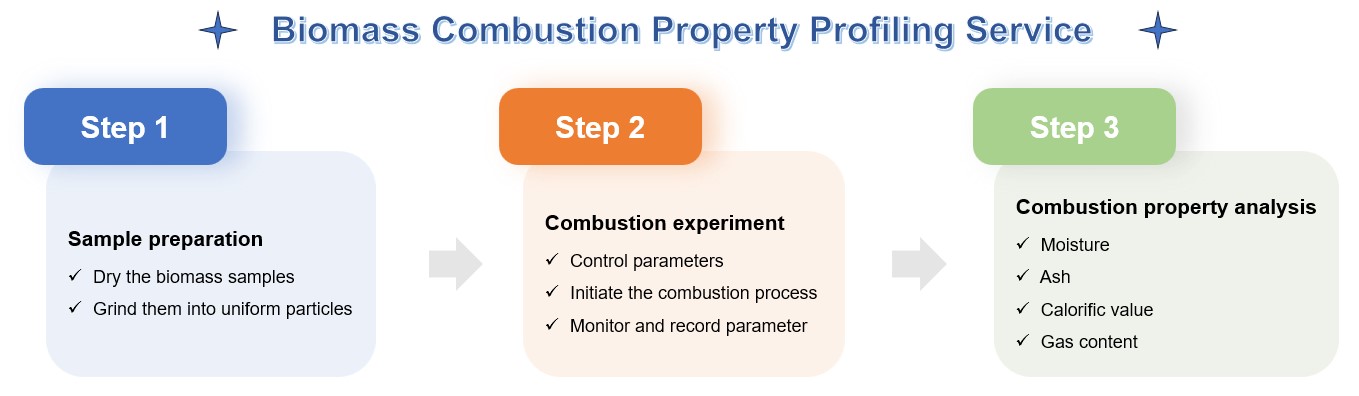

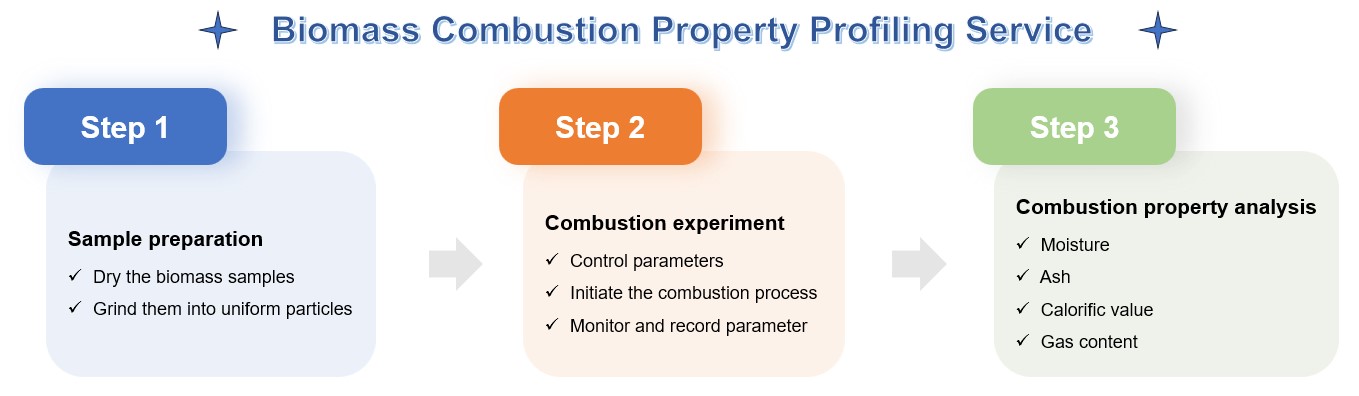

Biomass Combustion Property Profiling Service

Comprehensive Combustion Property Analysis for Biomass at Creative Biolabs

Biomass refers to organic matter from plants, animals, or microorganisms, which is of great significance in the energy field as a renewable resource. It includes primary biomass (such as trees), secondary biomass (such as agricultural waste), and waste biomass (such as garbage), which is used as biofuel for power generation, heating, gas production, etc., and is also used in chemical, biomedical and other fields. Combustion property analysis of biomass can evaluate the ash, calorific value, organic matter content, and other parameters generated by different types of biomass during the combustion process, help clients choose the fuel that best suits their needs, and optimize energy conversion efficiency, improve energy utilization efficiency and reduce energy costs. Creative Biolabs is equipped with advanced laboratory equipment, including combustion test equipment, gas analysis instruments, etc., and provides clients with custom biomass combustion property analysis services.

We fully dry the collected biomass samples and grind them into uniform particles to ensure the accuracy of the test.

We place the samples in a special combustion device, gradually increase the temperature, and initiate the combustion process by controlling parameters such as temperature and pressure, and monitor and record parameter changes in the combustion process in real-time, including heat release rate, gas emissions, ash content, and other data.

-

Combustion property analysis

High moisture content will reduce the combustion efficiency of biomass. We heat the biomass sample to a certain temperature under controlled conditions to evaporate the internal moisture. Then the weight lost by the sample during heating is measured by weighing method or oven drying method to calculate the moisture content. It helps to evaluate the dryness of biomass fuel and helps adjust combustion parameters, such as supplying the appropriate amount of oxygen, to improve combustion efficiency.

The inorganic residue left after the biomass sample is burned in a high-temperature furnace is the ash. Due to the composition of the biomass itself and its growth environment, certain cations, anions, and trace elements will exist in the ash. These inorganic components will form solid residues during the combustion process and play a vital role in combustion property and environmental impact. We use ion chromatography (IC) to analyze the main cations (such as Na+, K+, Ca2+, Mg2+, etc.) and anions (such as Cl-, SO42-, etc.) in the ash, and use inductively coupled plasma optical emission spectrometry (ICP-OES) to analyze the content of trace elements (such as titanium, lead, nickel, etc.). A comprehensive understanding of the various ions and elements in biomass ash provides more detailed chemical information for combustion properties and helps optimize biomass utilization.

Calorific value helps determine the energy released during biomass combustion. We use an oxygen bomb calorimeter to determine the higher heating value (HHV) of biomass, and a differential scanning calorimeter (DSC) or other heat capacity measuring instruments to determine the lower heating value (LHV) of biomass. Both can help evaluate the energy utilization potential of biomass as a fuel and provide important reference information for the rational utilization and energy conversion of biomass.

We use a gas chromatograph (GC) to monitor and record the gas components produced during the combustion process in real-time, such as CO2, CO, O2, etc. The gas composition data obtained by analysis can calculate the combustion efficiency during the combustion process and monitor and control the impact of gas on the environment.

Creative Biolabs has rich experience in combustion property analysis. We comprehensively consider the results of combustion property analysis and provide clients with comprehensive analysis solutions and suggestions to help clients improve energy utilization efficiency. In addition, we also provide Process Liquid and Physical Property Analysis services for biomass. Please contact us if you would like to obtain specific content.

Published data

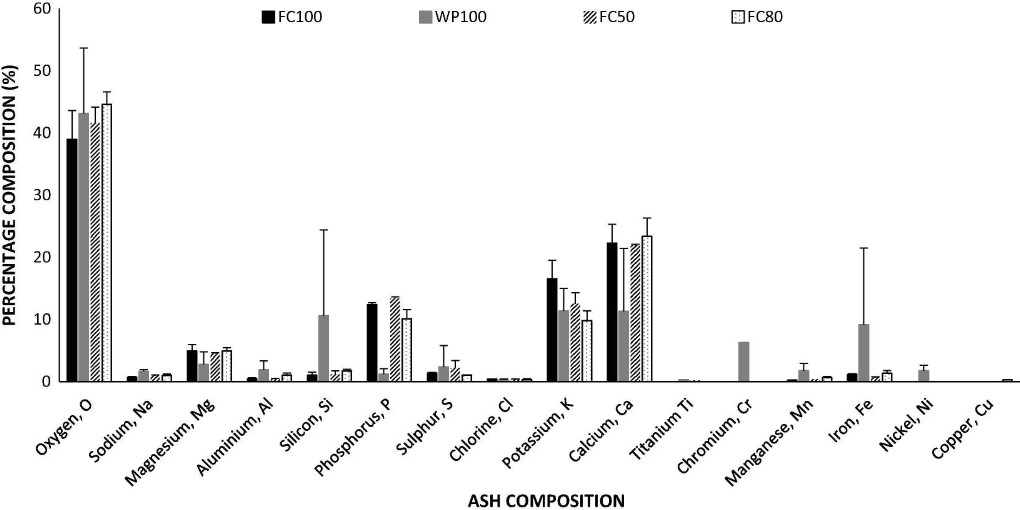

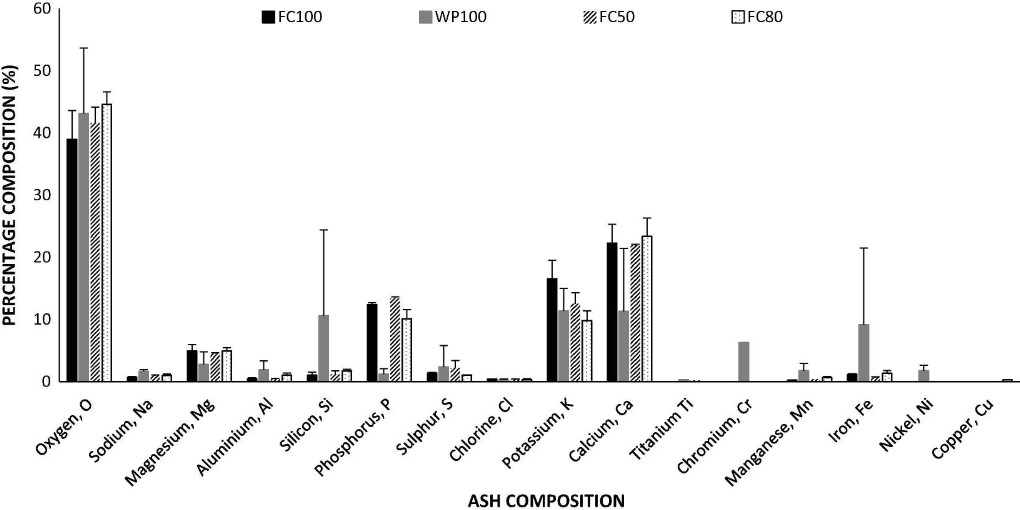

Fuel blending is a widely used method in biomass combustion, which aims to produce high-quality fuel products by combining two or more materials. Woody biomass, as a resource that is easily accessible and usable, plays a key role in this process. In this study, the authors conducted a mixed combustion experiment of wood chips and raw dung in a tabletop burner, exploring the combustion conditions under different air flow rates and mixing ratios to study the potential application of this fuel blending method in the development of new technologies. After the combustion experiment, the authors collected and weighed the ash and analyzed the residual carbon content in it. Moreover, the elemental composition of the ash samples was analyzed using energy-dispersive X-ray spectroscopy (EDX). The results showed that in addition to oxygen, the main elements in dung ash were calcium and potassium. In addition, it also contains common elements phosphorus and magnesium, while the contents of copper, nickel, manganese, iron, and aluminum are relatively small. This showed that dung ash might have the potential to be used as a soil conditioner.

Fig.1 Analysis of the elements in the ash of the original raw materials and some mixed fuels.1, 2

Fig.1 Analysis of the elements in the ash of the original raw materials and some mixed fuels.1, 2

FAQs

Q1: We will use different types of biomass as fuel. Could you help us compare their combustion property?

A1: Of course, we test and compare the combustion performance of different types of biomass samples for you to help you choose the fuel that best suits your project needs.

Q2: What specific content does your combustion property analysis service include? How can we obtain the test report?

A2: Our services cover calorific value testing, ash analysis, moisture testing, and other aspects. You can send the sample to our laboratory for testing, and we will provide you with a detailed test report and explain the meaning of each parameter and its impact on your project.

Q3: We need to adjust the production process according to the test results. Can you provide relevant suggestions?

A3: Yes, our professional teams provide you with production process suggestions for biomass combustion performance according to the test results to help you optimize the production process and improve efficiency.

Customer Review

Professional Data Analysis Capabilities for Biomass Combustion Performance

"We are very satisfied with the biomass combustion property analysis service provided by Creative Biolabs. We are impressed by their professional level and data processing capabilities. We look forward to future cooperation opportunities! "

Helps Clients Optimize Biomass Combustion Efficiency

"We are impressed by the biomass combustion performance analysis service provided by the Creative Biolabs team. Their professional team provided us with valuable data and suggestions to help us optimize the combustion process and improve energy efficiency."

References

-

Somorin, Tosin Onabanjo, et al. "Faecal-wood biomass co-combustion and ash composition analysis." Fuel 203 (2017): 781-791.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Analysis of the elements in the ash of the original raw materials and some mixed fuels.1, 2

Fig.1 Analysis of the elements in the ash of the original raw materials and some mixed fuels.1, 2