Enzymatic Decomposition Reaction-based Fermentation Inhibitors Analysis Service

Mature Fermentation Inhibitor Analysis Services in Enzymatic Hydrolysates at Creative Biolabs

In biomass conversion and biofuel production processes, biomass materials are typically converted into fermentable sugars through enzymatic hydrolysis. However, enzymatic hydrolysis products may contain some compounds that inhibit the subsequent fermentation process, called fermentation inhibitors. Analyze fermentation inhibitors in enzymatic hydrolysis products and evaluate the type, concentration, and impact of potential fermentation inhibitors present in enzymatic hydrolysis products to optimize the subsequent fermentation process and improve the yield and quality of biofuels or biochemical products.

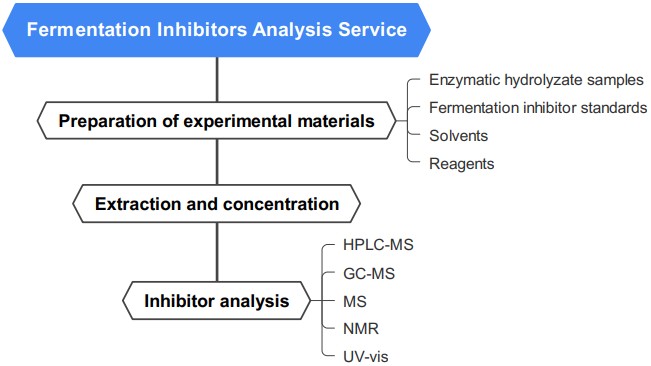

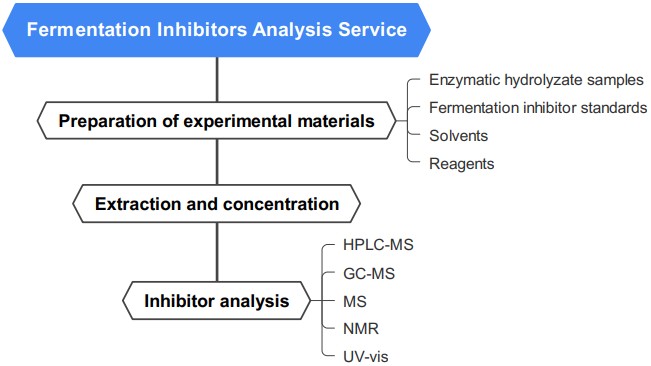

Creative Biolabs has a professional team with deep expertise and rich experience in the fields of biotechnology, chemical analysis, and biochemical engineering, we accurately identify, analyze, and quantify fermentation inhibitors in enzymatic hydrolysis products. Common inhibitors include phenols, aldehydes, acids, etc., which may harm the growth and metabolism of microorganisms during fermentation. By analyzing these inhibitors, clients can be guided to take appropriate measures to mitigate the adverse effects of these inhibitors on the fermentation process, thereby improving production efficiency and product quality. Analysis of fermentation inhibitors in enzymatic hydrolysates usually involves the following steps.

-

Preparation of experimental materials

We prepare a variety of experimental materials and reagents according to the designed analysis plan, including enzymatic hydrolyzate samples, fermentation inhibitor standards, solvents (such as methanol, acetonitrile, etc.), and reagents required for various instrumental analyses.

-

Extraction and concentration

We take samples from the enzymatic hydrolyzate and perform appropriate pre-treatment steps (such as filtration, dilution, etc.) on the samples, and then use appropriate extraction methods (such as solid-phase extraction, and liquid-liquid extraction) to extract potential inhibitors from the enzymatic hydrolyzate. The extract is concentrated for subsequent instrumental analysis.

According to the physical and chemical properties of the inhibitors, we use the standard curve method or the internal standard method to analyze the fermentation inhibitors in the enzymatic hydrolyzate through various analytical methods, including formic acid, acetic acid, levulinic acid, furfural, and hydroxymethylfurfural.

-

High-performance liquid chromatography-mass spectrometry (HPLC-MS): This technology combines HPLC and MS, which are used to detect and quantify various organic compounds.

-

Gas chromatography (GC)-MS: This technology can analyze volatile organic compounds in enzymatic hydrolyzate, such as alcohols or aldehydes.

-

MS: We use MS techniques (such as time-of-flight mass spectrometry) to analyze enzymatic digests to determine the structure and composition of unknown compounds.

-

Other analysis methods: Depending on specific needs, we also use other analysis methods, such as nuclear magnetic resonance (NMR) and ultraviolet-visible spectroscopy (UV-vis), to analyze fermentation inhibitors in enzymatic hydrolyzate.

After the analysis is completed, we compare the retention time and peak area of the target compound in the sample with the standard to identify and quantitatively analyze the fermentation inhibitors in the enzymatic hydrolyzate.

Fig.1 Fermentation inhibitor extraction and analysis services.

Fig.1 Fermentation inhibitor extraction and analysis services.

Creative Biolabs provides comprehensive fermentation inhibitor analysis services in enzymatic hydrolysates to help optimize biomass conversion and biofuel production processes. Specific steps in the process may be adjusted according to actual circumstances and analysis needs. In addition, we also provide Enzyme Degradation Efficiency Analysis, Residue Content Analysis, Enzyme-Mediated Saccharification Efficiency Analysis, and Enzyme and Catabolic Enzyme Activity Assessment services. Please contact us if you would like to acquire our service.

Published data

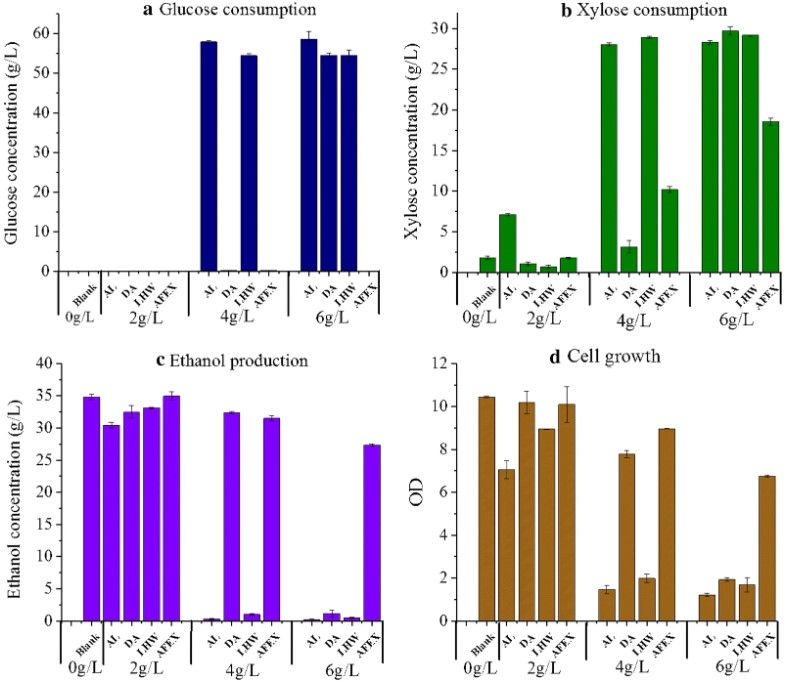

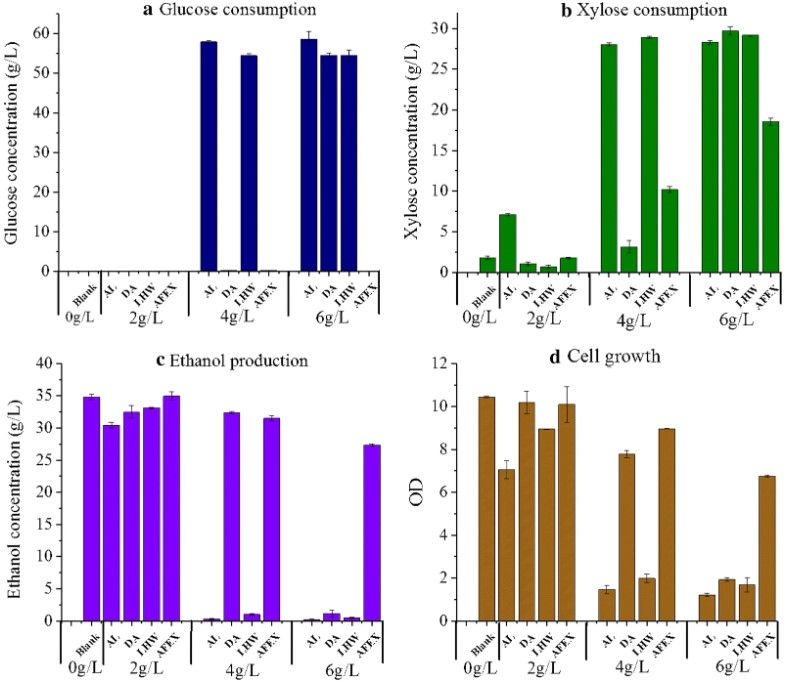

Lignocellulosic biomass is used to produce bioethanol, while this process is inhibited by a variety of inhibitors. When lignin is pretreated, phenolic substances are produced that are inhibitory to enzymatic hydrolysis and fermentation processes. Therefore, different pretreatment methods may affect the structure of phenolic substances, thereby inhibiting the biotransformation process to varying degrees. The authors treated lignin through four pretreatment methods (dilute acid (DA), alkaline (AL), ammonia fiber expansion (AFEX), and liquid hot water pretreatment (LHW)) and evaluated the effect of the produced phenolic compounds on the enzymatic hydrolysis and fermentation processes. The results showed that the inhibitory effect of phenols on enzymatic hydrolysis is AFEX>LHW>DA>AL and the inhibitory effect on bacterial fermentation is AL>LHW>DA>AFEX. The reason for this difference may be the influence of the amide groups in the phenolic resin. The authors believed that this research could provide new strategies to improve the efficiency of enzymatic hydrolysis and fermentation, thereby minimizing the inhibitory effects caused by phenolic substances.

Fig.2 Inhibitory effects of different pretreatment methods on strain fermentation.1, 2

Fig.2 Inhibitory effects of different pretreatment methods on strain fermentation.1, 2

FAQs

Q1: What are the common fermentation inhibitors found in enzymatic hydrolysates?

A1: Common fermentation inhibitors include organic acids (such as acetic acid, and formic acid), furan derivatives (e.g., furfural, HMF), phenolic compounds, and aliphatic alcohols (such as methanol). These inhibitors can affect microbial growth and fermentation efficiency.

Q2: What strategies can be employed to mitigate the effects of fermentation inhibitors?

A2: Strategies include detoxification methods such as physical treatments (e.g., activated carbon adsorption), chemical treatments (e.g., overliming, use of reducing agents), biological methods (employing inhibitor-tolerant strains), and process optimization (adjusting pH, temperature, nutrient supplementation).

Q3: How can you quantify the levels of fermentation inhibitors in enzymatic hydrolysates?

A3: This can be done through various analytical techniques like HPLC, GC-MS, spectrophotometry, or specific assays for individual inhibitors.

Customer Review

Custom Analysis

"The analysis of fermentation inhibitors in enzymatic hydrolysates was exceptionally detailed and well-presented. The recommendations provided by Creative Biolabs were practical and tailored to our specific needs, leading to significant improvements in our fermentation process."

Professional

"We were highly impressed by the professionalism and expertise displayed in the analysis of fermentation inhibitors. The insights provided by Creative Biolabs were instrumental in helping us optimize our processes and achieve higher yields. We look forward to continuing this valuable partnership."

References

-

Chen, Xiangxue, et al. "Understanding the structural characteristics of water-soluble phenolic compounds from four pretreatments of corn stover and their inhibitory effects on enzymatic hydrolysis and fermentation." Biotechnology for Biofuels 13 (2020): 1-13.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Fermentation inhibitor extraction and analysis services.

Fig.1 Fermentation inhibitor extraction and analysis services.

Fig.2 Inhibitory effects of different pretreatment methods on strain fermentation.1, 2

Fig.2 Inhibitory effects of different pretreatment methods on strain fermentation.1, 2