Biomass Physical Property Characterization Service

Trustworthy Physical Properties Analysis in Biomass at Creative Biolabs

Creative Biolabs has an experienced team of biomass analysis experts. We provide a variety of Biomass-related Analysis Services, such as Lignocellulose Composition analysis, physical properties analysis, and Anaerobic Digestion analysis services. Comprehensive physical property analysis of biomass helps to understand the characteristics of biomass and provides data support for its effective use.

We grind the biomass sample, then measure the particle size distribution of the particles with a laser particle size analyzer, and observe the morphological characteristics of the particles with a microscope.

We provide clients with comprehensive characterization of the basic density and bulk density of biomass. Basic density is an inherent property of biomass and is calculated by measuring the mass and volume of biomass samples after drying. Bulk density refers to the mass of a biomass sample within a given volume, which is affected by the shape and arrangement of particles and is often used to describe the compactness of materials in practical applications. We measure the bulk density of biomass using containers of known volume, which helps clients better understand the density characteristics of biomass samples and guide subsequent processing, transportation, and utilization processes.

The pore structure inside biomass affects its adsorption performance and air permeability. We use nitrogen adsorption to determine the porosity of biomass.

Accurate moisture content is very important for controlling the quality and stability of biomass materials. We use drying and titration methods to determine the moisture content in biomass samples to help clients evaluate the moisture state of biomass materials and guide their application in storage, processing, transportation, etc.

Creative Biolabs is equipped with advanced biomass analysis instruments that meet the testing needs of various types of biomass samples. We are committed to providing clients with comprehensive biomass physical property characterization services. We will win the trust of clients through our robust service quality and professional level. Please contact us if you need to consult our services, we look forward to cooperating with you.

Published data

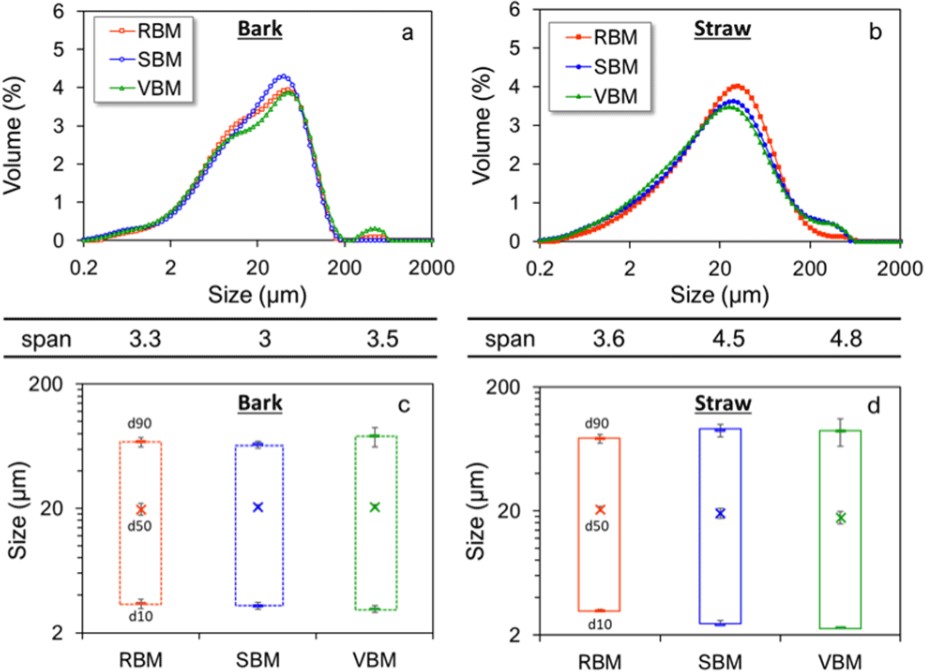

Lignocellulosic biomass is considered to have broad application potential and plays a key role in the fields of materials, chemistry, and energy. To increase the reactivity of biomass, it is often necessary to grind it into an ultrafine powder to increase its surface area. The authors used three devices: a rotating ball mill (RBM), stirrer ball mill (SBM), and vibrating ball mill (VBM) to explore the effect of mechanical force on the properties of wheat straw and pine bark, two common lignocellulosic materials. They measured the particle size distribution (PSD) of the biomass powder by dry and wet methods using a Malvern laser diffraction particle sizer and analyzed the shape and flowability of the granular powder using a particle characterization system and a powder rheometer. The research results showed that pine bark became more uniformly powdered after ultra-fine grinding. Except for SBM, its PSD curves showed a bimodal distribution in the other two grinding methods. Moreover, the d10, d50, and d90 size values produced by different ball mills were very similar. However, for straw, the span value of the PSD curve increased significantly to 4.8 during ultra-fine grinding, revealing the heterogeneity of straw. After integrating all the characterization data, the authors found that pine bark was easier to grind than wheat straw, but its powder dispersibility and compressibility were poor. In addition, the authors also found that the SBM ball mill could provide complementary friction and impact forces and was considered to be the best choice for the efficient refinement of lignocellulose.

Fig.1 Particle size and distribution of bark (a, c) and straw (b, d) powders.1, 2

Fig.1 Particle size and distribution of bark (a, c) and straw (b, d) powders.1, 2

FAQs

Q1: Regarding the specific physical properties of biomass samples, have you analyzed similar samples?

A1: Yes, we have completed the analysis of many types of biomass samples, including wood pellets, straw, corn stover, etc. We have extensive experience in handling a variety of biomass samples.

Q2: What physical properties do you include in your analysis services? Can we customize them as needed?

A2: The services we provide cover multiple physical property parameters, such as particle size, density, porosity, etc. We can customize the analysis plan according to client needs.

Q3: Which physical property indicators are most important for my research project? Which parameters do you think should be prioritized?

A3: Depending on the needs of your research project, we recommend prioritizing the physical property indicators that have the greatest impact on your research, such as whether the particle size is critical to your specific application.

Customer Review

Provide Targeted Solutions According to Biomass Physical Analysis Results

"We chose Creative Biolabs laboratory when looking for biomass physical properties analysis services, and their professional level is satisfactory. They not only conducted accurate tests on the samples but also provided targeted suggestions and solutions. We are very satisfied and look forward to future cooperation!"

Efficiently Deliver Biomass Analysis Reports

"Creative Biolabs completed the physical analysis of the biomass in a short time and delivered the report promptly, which provided important support for our project progress. I highly recommend their analysis services."

References

-

Rajaonarivony, Rova Karine, et al. "Properties of biomass powders resulting from the fine comminution of lignocellulosic feedstocks by three types of ball-mill set-up." Open Research Europe 1 (2021).

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Particle size and distribution of bark (a, c) and straw (b, d) powders.1, 2

Fig.1 Particle size and distribution of bark (a, c) and straw (b, d) powders.1, 2