Degree of Acetylation Determination Service

Services Published Data FAQs Customer Review

Professional Analysis of Degree of Acetylation at Creative Biolabs

The degree of acetylation is one of the key parameters in the biomass processing process. The degree of acetylation directly affects the performance and characteristics of biomass products, such as solubility, thermal stability, biodegradability, etc. Analysis of the degree of acetylation helps control product consistency and quality stability. Moreover, according to the needs of different degrees of acetylation, the biomass processing technology can be adjusted and optimized to increase productivity. Creative Biolabs has established an advanced In-process Chemical Composition Analysis platform. Based on this platform, we provide professional analysis services for Sugars, Sugar Degradation Products, Esterification Degrees, and acetylation degrees. Acetylation analysis of biomass process liquids can ensure product quality, optimize processes, and expand product application areas. This analysis process is crucial to the development and sustainability of the biomass processing industry.

Our scientists have extensive experience and expertise in providing high-quality acetylation analysis services through a variety of techniques.

-

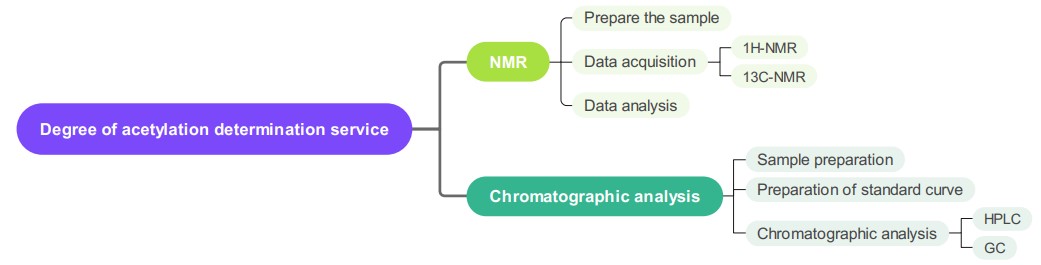

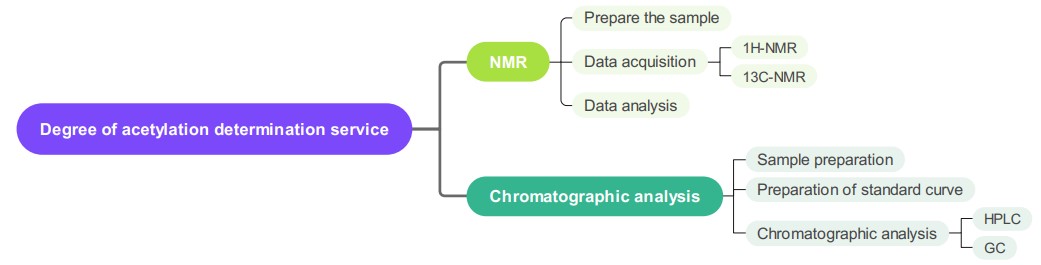

Nuclear magnetic resonance (NMR)

-

Prepare the sample: We dissolve the biomass process liquid sample in an appropriate solvent to obtain a clear NMR spectrum.

-

Data acquisition: Then we use high-resolution NMR instruments for data acquisition, and obtain high-quality NMR spectra by setting appropriate pulse sequences and parameters. Commonly used types of NMR include 1H-NMR and 13C-NMR.

-

Data analysis: We analyze the NMR spectrum of the sample and compare the characteristic peak area or peak intensity of acetylated products and non-acetylated products to calculate the relative percentage of acetylation degree. According to the data obtained from the analysis, the content of acetylation degree in the biomass process liquid is obtained.

-

Chromatographic analysis

-

Sample preparation: We perform steps such as extraction, purification, or pretreatment of biomass process liquid samples, and ensure that the sample preparation process does not interfere with the analysis.

-

Preparation of standard curve: We prepare a series of standard solutions containing known degrees of acetylation for subsequent analysis and quantitative calculations.

-

Chromatographic analysis: We select an appropriate chromatography method, such as high-performance liquid chromatography (HPLC) or gas chromatography (GC), and introduce the processed samples and standard solutions into the analysis system through an automatic injector. After running the analysis program, we record the peak shape, retention time, and peak area of the acetylated and unacetylated products in the sample, and compare them with the standard curve to calculate the acetylation content.

In addition, we also analyze the degree of acetylation in biomass process liquids through mass spectrometry (MS) technology, which is a process in which molecules in the sample are decomposed into fragmented ions by a mass spectrometer and detected and analyzed according to the mass-to-charge ratio. It has the advantages of high sensitivity and selectivity and is used to identify and quantify compounds, including acetylation products.

Creative Biolabs has mastered the latest analytical technologies and methods, such as HPLC, NMR, etc. We provide clients with high-quality, professional biomass process liquid acetylation degree analysis services and meet client requirements and expectations. If you are looking for a professional acetylation analysis facility for your biomass process liquid samples, we are your best partner. Please contact us and we will respond quickly to your needs.

Published data

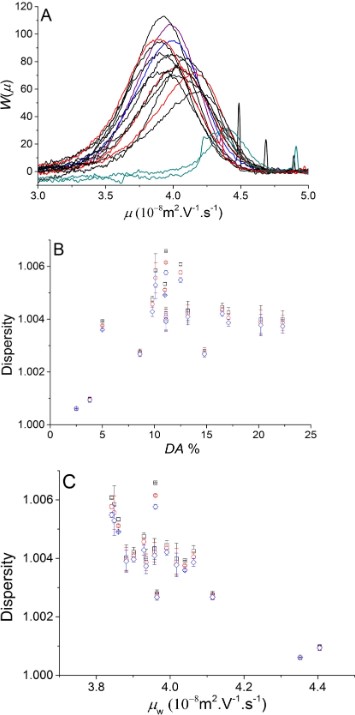

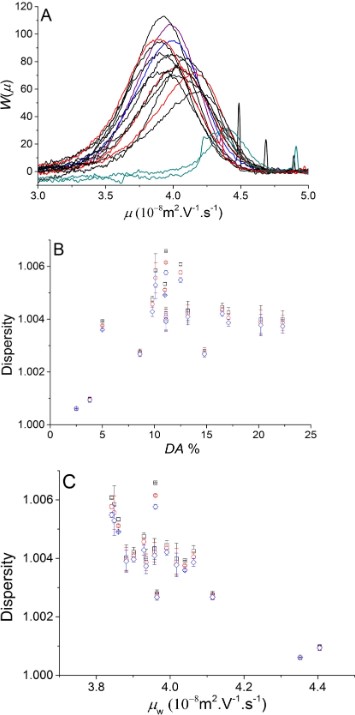

Lignin can be used as a potential source of chemicals and fuel. In this study, the authors used a novel pressurized water extraction (PHWE) process to extract lignin from different plants and derivatized the lignin by methylation and acetylation. Then, the authors characterized the structure and thermal properties of lignin and its derivatives in detail by NMR and thermos-gravimetric analysis techniques and determined the degree of substitution of methylated and acetylated lignin. The results showed that the structure of lignin was rich in carboxyl and phenolic groups, which was conducive to chemical modification operations such as methylation and acetylation, thereby regulating the chemical properties of lignin. Through this study, the authors believed that this lignin and its derivatives had broad application prospects in polymer blends.

Fig.1 Structural and thermal analysis scheme of lignin and its modified derivatives.1

Fig.1 Structural and thermal analysis scheme of lignin and its modified derivatives.1

FAQ

Q1: Why is it necessary to analyze the degree of acetylation in biomass process liquids?

A1: Acetylation degree analysis can help clients evaluate the biomass modification effect, control the production process, optimize biomass utilization plans, and understand the composition of products produced after biomass treatment.

Q2: Can acetylation degree analysis be quantified?

A2: Yes, we accurately measure the degree of acetylation in biomass process liquids by establishing a standard curve or using internal standard materials for quantitative analysis.

Q3: How to interpret the data results of acetylation degree analysis?

A3: By comparing the content of acetylated products and unacetylated products in a sample, we calculate the percentage of acetylation degree to understand the relative number of acetyl groups in the biomass, which helps to quantitatively assess the degree of chemical modification of the biomass.

Customer Review

Reliable and Accurate Analytical Results

"We are very grateful to Creative Biolabs for providing the acetylation degree analysis report. The results are very reliable and accurate. These data provide us with an in-depth understanding of the degree of acetylation reaction during biomass processing and are crucial for our future research and development work."

Clear and Understandable Results

"I am very impressed with the acetylation analysis results you provided. The data charts in the report are clear and the explanations are very easy to understand. This helps us better understand acetylation in biomass process liquids. Thank you for your professional analysis and communication."

Reference

-

Lagerquist, Lucas, et al. "Structural and thermal analysis of softwood lignins from a pressurized hot water extraction biorefinery process and modified derivatives." Molecules 24.2 (2019): 335. Distributed under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Structural and thermal analysis scheme of lignin and its modified derivatives.1

Fig.1 Structural and thermal analysis scheme of lignin and its modified derivatives.1