Carbohydrate Compositions Quantitative Profiling Service

Accurate Lignocellulosic Sugar Analysis to Power Client Research

Lignocellulose is the largest renewable biomass feedstock on earth. Its related Ash Content Analysis, Extractive Analysis, lignocellulosic sugar analysis, etc., are crucial for understanding the composition and processing of Biomass such as Lignocellulose. Creative Biolabs provides a high-quality lignocellulose sugar analysis service including monosaccharides for various lignocellulosic materials to support our clients' biomass research.

Our expert scientists have optimized the processes involved in lignocellulosic sugar analysis. The analytical methods are simple. The results are accurate and precise. We are also equipped with advanced analytical equipment. All samples are analyzed in duplicate for lignocellulosic sugars.

-

Analyzed items

-

Total sugar content (hemicellulosic and cellulosic)

-

Glucose: Glucose is found mainly in cellulose and is considered a good indicator of the cellulose content of the raw material.

-

Mannose: Mannose is found mainly in hemicellulose, but also in xylan and other hemicelluloses.

-

Rhamnose: Rhamnose is found in some hemicelluloses and is a major component of pectin.

-

Xylose: Xylose is found mainly in hemicellulose, and is the most abundant sugar in xylan.

-

Galactose: Galactose is found mainly in hemicellulose, but also in xylan and other hemicelluloses.

-

Arabinose: Arabinose is found mainly in hemicellulose, especially in xylan and arabinogalactan.

-

Analysis step

-

Acid hydrolysis of the sample: The sample is subjected to acid hydrolysis.

-

The treatment of hydrolysis products: After the acid hydrolysis treatment of the sample, the hydrolysis products are diluted using an aqueous fucose solution. The diluted sample is placed in the refrigerator to be used or analyzed directly through the chromatographic system.

-

Chromatographic analysis: Fucose is used as an internal standard and the diluted samples are analyzed by ion chromatography (IC).

Fig.1 Process of sugar analysis including monosaccharides in lignocellulose.

Fig.1 Process of sugar analysis including monosaccharides in lignocellulose.

Advantages of Lignocellulosic Sugar Analysis

-

Experimental flexibility: We flexibly adjust the lignocellulosic sugar analysis process in time according to the actual requirements of clients and the types of samples provided.

-

Experienced scientists: Our experienced laboratory staff conducts experiments according to strict specifications with high reproducibility.

-

Accurate delivery: We have a strict project management system to ensure timely delivery of results.

Lignocellulosic sugar analysis is an integral part of the development and optimization of lignocellulosic conversion processes, helping to determine the suitability of different lignocelluloses for a particular conversion pathway. Creative Biolabs provides a very professional lignocellulosic sugar analysis service to assist lignocellulosic research. Welcome to contact us for more information and a detailed quote on lignocellulosic sugar analysis.

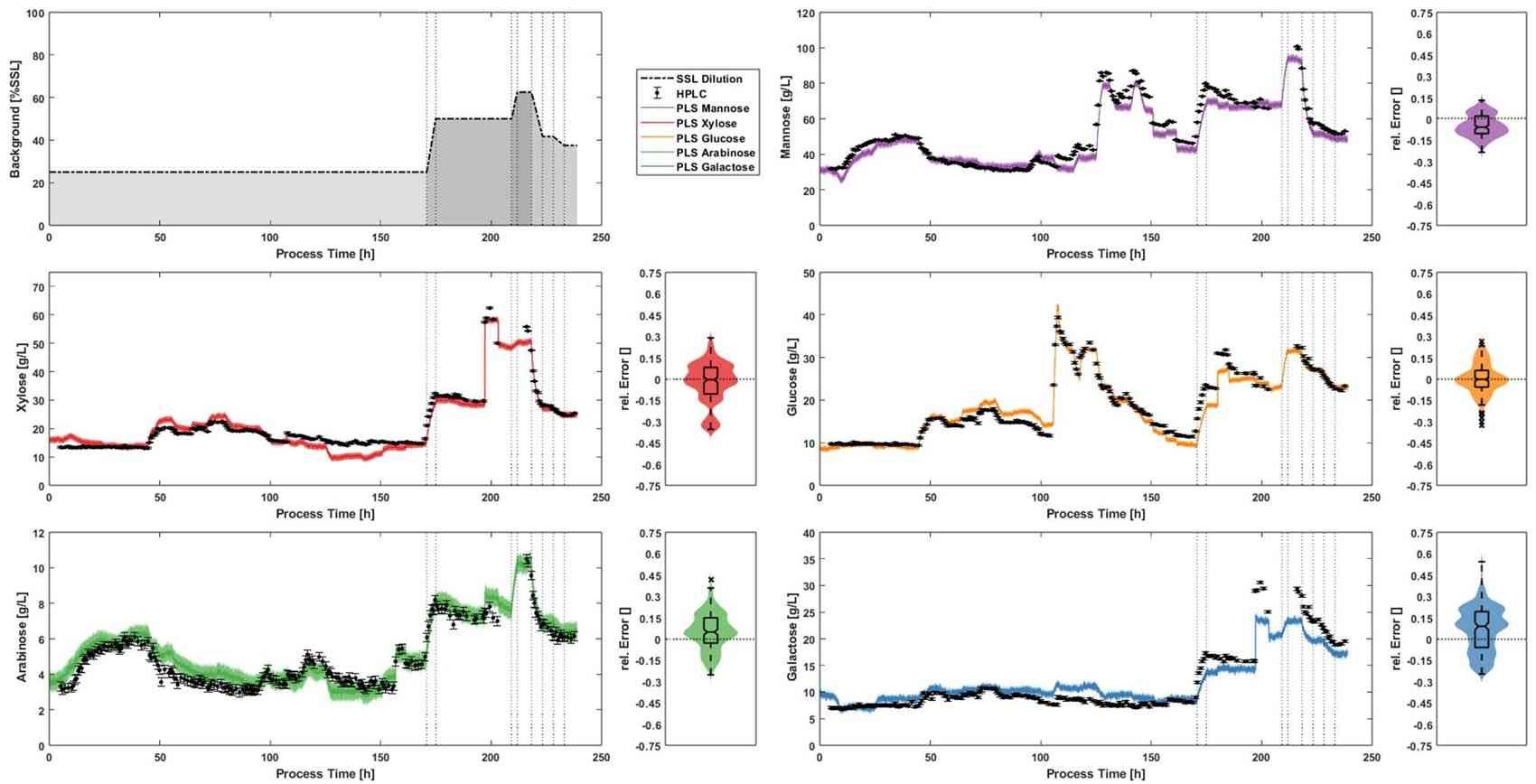

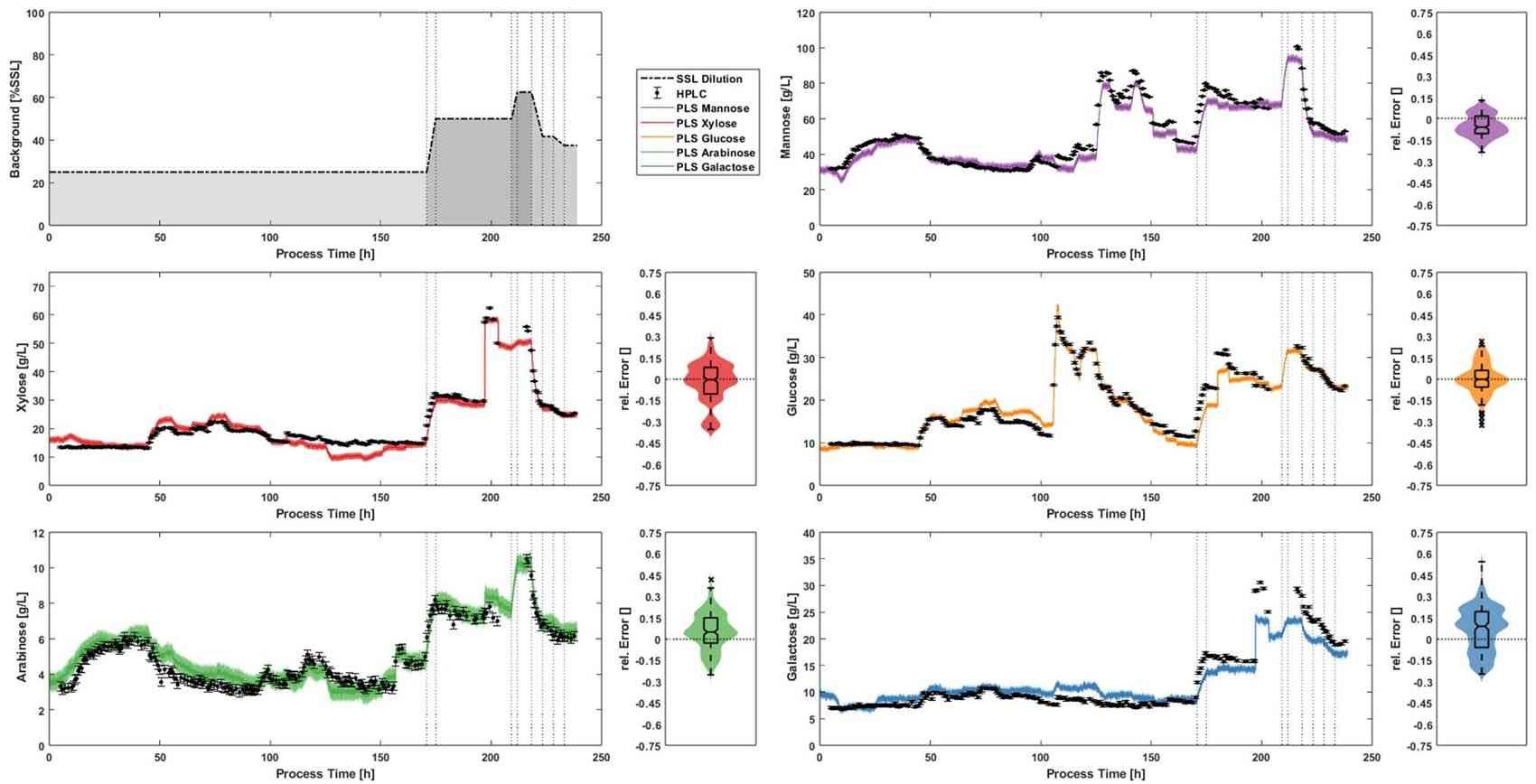

Published data

Lignocellulosic composition analysis is crucial for lignocellulosic processing optimization. Therefore there is an urgent need to develop a method that detects lignocellulosic sugar content in real-time. In this study, to solve this problem, a spectroscopy-based process analytical technique (PAT) strategy for real-time determination of sugar composition in lignocellulosic processing waste streams was proposed through continuous exploration and validation. The method allowed the simultaneous quantification of up to five sugars (xylose, arabinose, glucose, mannose, and galactose). The advantage of this method lay in its ability to simultaneously quantify multiple sugars in complex matrices compared to previous similar spectroscopic methods that only detect lignocellulosic residues after milder enzymatic or acid pretreatment. This study provided theoretical and data support for efficient lignocellulosic sugar analysis.

Fig.2 In-line application of the developed models.1, 2

Fig.2 In-line application of the developed models.1, 2

FAQs

Q1: Does the sample need to be pre-treated?

A1: Samples are usually treated directly with acid without extraction. If the samples are treated by extraction before analysis of lignocellulosic sugar, the extracted material is subjected to acid treatment. In addition to this, samples extracted with water and ethanol are also used for acid hydrolysis treatment.

Q2: Are samples typically analyzed once or twice?

A2: The data obtained in scientific experiments are often subject to errors. If we want to minimize the error, we need to repeat the same experiment several times under the same conditions. Therefore, all our samples are divided into two and analyzed twice.

Customer Review

Detailed Sugar Analysis

"As a high-tech company focusing on biomass processing, we faced some challenges in the optimization of pretreatment and conversion processes for lignocellulose. Working with Creative Biolabs was a good turning point for us. They were very experienced in lignocellulosic sugar analysis. The detailed analysis provided us with detailed information on the sugar composition of various lignocellulosics and allowed us to discover the best way to treat these lignocelluloses. That was crucial for us to assess the quality, variability, and potential applications of different biomass feedstocks."

Accurate and Detailed Fulfillment of Analysis Needs

"We needed lignocellulosic sugar analysis to learn important information about the composition and concentration of sugars in lignocellulosic feedstocks. This information was critical for optimizing lignocellulosic conversion processes and estimating potential bioenergy yields. Therefore, we have been working with Creative Biolabs. They were very professional and contacted us promptly during the lignocellulosic sugar analysis process to ensure that our needs were met with precision and care."

References

-

Waldschitz, Daniel, et al. "Addressing raw material variability: In-line FTIR sugar composition analysis of lignocellulosic process streams." Bioresource Technology 399 (2024): 130535.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Process of sugar analysis including monosaccharides in lignocellulose.

Fig.1 Process of sugar analysis including monosaccharides in lignocellulose.

Fig.2 In-line application of the developed models.1, 2

Fig.2 In-line application of the developed models.1, 2