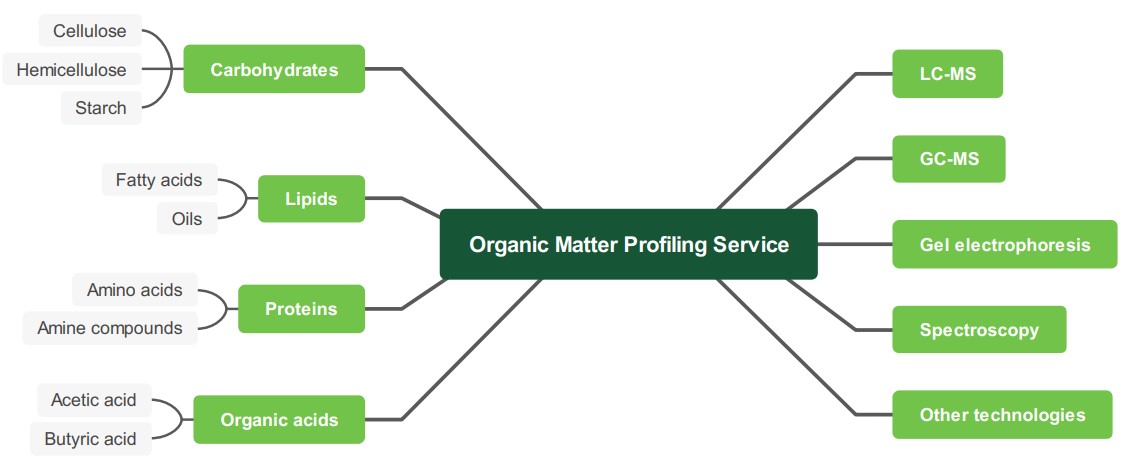

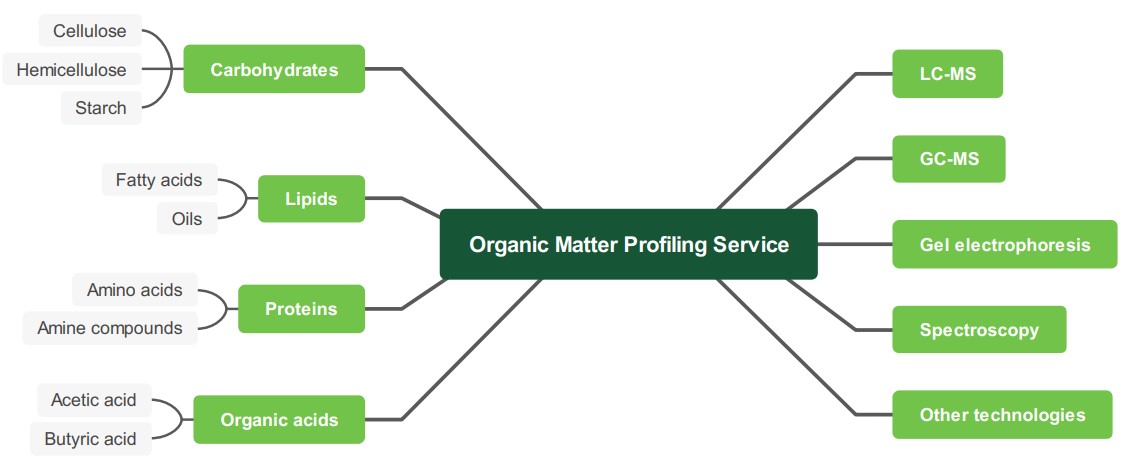

Organic Matter Profiling Service

A Full Range of Organic Matter Analysis Services in the Anaerobic Digestion Process at Creative Biolabs

Anaerobic digestion is a biochemical process in which microorganisms decompose organic waste in a completely oxygen-deficient environment to produce biogas and organic fertilizer. During the anaerobic digestion process, many organic substances are produced. A reasonable analysis of the composition, concentration, and properties of organic substances helps optimize the anaerobic digestion process, determine the biogas potential of raw materials, and improve production efficiency and biogas quality. Creative Biolabs has established a complete quality analysis management system, and our experienced scientific research teams provide custom analysis for different samples.

For the anaerobic digestion process, we provide a variety of organic matter analysis services:

-

Carbohydrates: Such as cellulose, hemicellulose, starch, etc., which are mainly derived from plant residues and food waste. These are the main carbon sources for anaerobic digestion. Analyzing their content helps evaluate the gas production potential and digestion efficiency.

-

Lipids: Such as fatty acids and oils, which are mainly derived from food processing waste, kitchen waste, etc., and are one of the important sources of organic matter for biogas generation. Analyzing the content of fat substances helps optimize the internal environment of the reactor and increase biogas production.

-

Proteins: Such as amino acids, amine compounds, etc., mainly come from animal feces, food waste, etc. Protein analysis is used to understand nitrogen balance and promote the biogas production process.

-

Organic acids: Such as acetic acid and butyric acid, are intermediate products produced during anaerobic digestion, affecting fermentation rate and gas production. Analyzing the content of organic acids helps monitor the status of the reactor and prevent abnormal conditions.

These organic substances are degraded by microorganisms during anaerobic digestion, producing gases such as methane as energy and organic fertilizer. By analyzing these organic substances, the efficiency of the digestion process is evaluated, the stability of the reactor is monitored, and the technology is optimized to increase production capacity and reduce waste. We mainly use high-performance liquid chromatography-mass spectrometry (LC-MS), gas chromatography-mass spectrometry (GC-MS), gel electrophoresis, spectroscopy, and other technologies to comprehensively analyze the types and contents of organic matter present in the anaerobic digestion process.

In addition to organic matter analysis, Creative Biolabs also provides clients with a full range of Anaerobic Digestion analysis and support services, such as Biomethane Potential, Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Digestate Impurity Content, and other analysis services. We pay great attention to client needs to provide custom analysis services according to the client's specific requirements and communicate in a timely and effective manner. If you would like to consult about specific services, please contact us and we will meet your various needs.

Published data

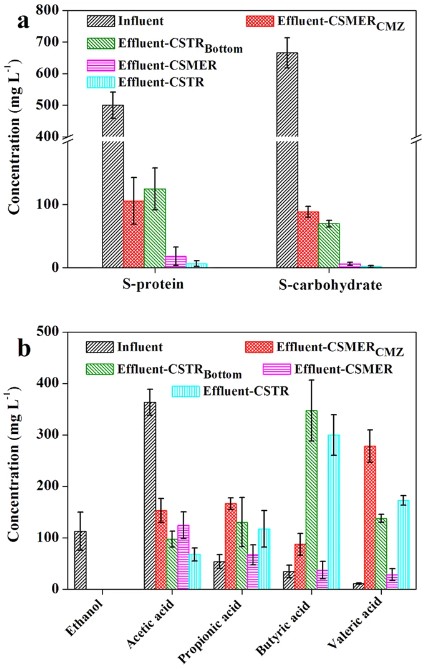

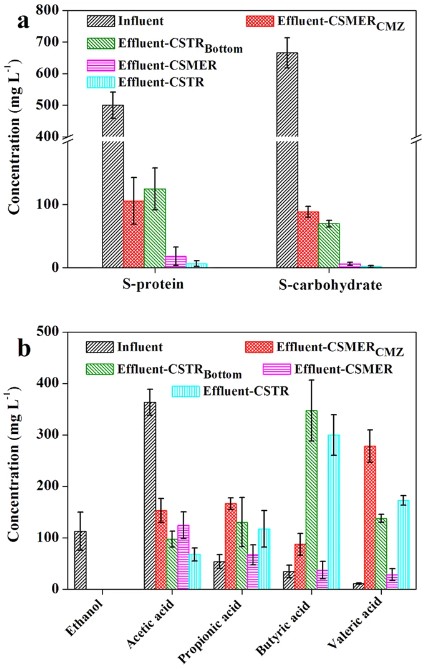

During the brewing process, a large amount of wastewater is generated. These wastewaters are rich in high concentrations of soluble proteins, carbohydrates, and volatile fatty acids (VFAs), which are easily biodegradable and therefore particularly suitable for further biological treatment of wastewater using biological treatment methods. There are many methods for treating brewery wastewater, including aerobic treatment, anaerobic treatment, and the application of anaerobic bioreactors. In this study, the authors designed and used a continuously stirred microbial electrochemical reactor (CSMER) to treat brewery wastewater. The reactor consists of two parts: a microbial electrochemical zone (MEZ) and a complete mixing zone (CMZ). During the treatment process, most of the soluble carbohydrates and proteins in the wastewater in the CMZ area were anaerobically digested and converted into VFAs, mainly ethanol and other short-chain acidic compounds. These VFAs and residual organic matter were then further decomposed in the MEZ and used to generate electricity, thereby not only recovering energy but also optimizing the effluent quality. The CSMER exhibited efficient pre-hydrolysis and acidification rates, high energy recovery rates, and low treatment costs in the application of brewery wastewater treatment, showing its great application potential in actual wastewater treatment.

Fig.1 Analysis of results of various components in the CSMER reactor.1, 2

Fig.1 Analysis of results of various components in the CSMER reactor.1, 2

FAQs

Q1: We need to understand the impact of organic matter on biogas production, can you provide this information from the analysis?

A1: Yes, through organic matter analysis, we evaluate the impact of different organic matter on the biogas fermentation process, thereby helping to optimize gas production efficiency.

Q2: Can the analysis be performed for specific organic matter?

A2: Yes, please tell us the organic matter you are interested in and we customize the analysis according to your needs.

Q3: Can you provide technical support and consulting services during the analysis?

A3: Yes, our team will provide you with technical support and professional consulting services throughout the analysis process to ensure that you have a clear understanding of the analysis results.

Customer Review

Excellent Client Experience

"Excellent client service experience. Creative Biolabs's laboratory team patiently answered all our questions about organic analysis, which made us very satisfied."

Reliable Organic Analysis Supports Research Projects

"Excellent organic analysis service, professional and reliable, played a key role in the success of our project. Thank you very much for the support of the Creative Biolabs team!"

References

-

Wang, Haiman, et al. "Cascade degradation of organic matters in brewery wastewater using a continuous stirred microbial electrochemical reactor and analysis of microbial communities." Scientific Reports 6.1 (2016): 27023.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Analysis of results of various components in the CSMER reactor.1, 2

Fig.1 Analysis of results of various components in the CSMER reactor.1, 2