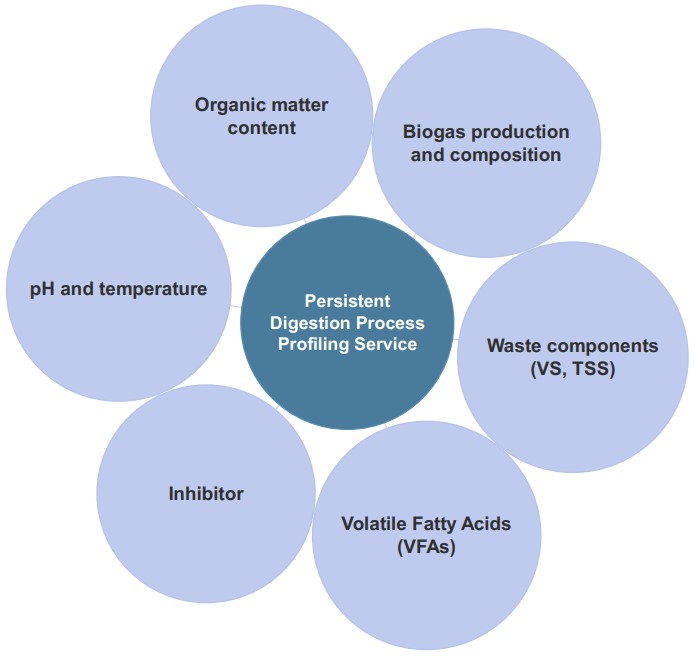

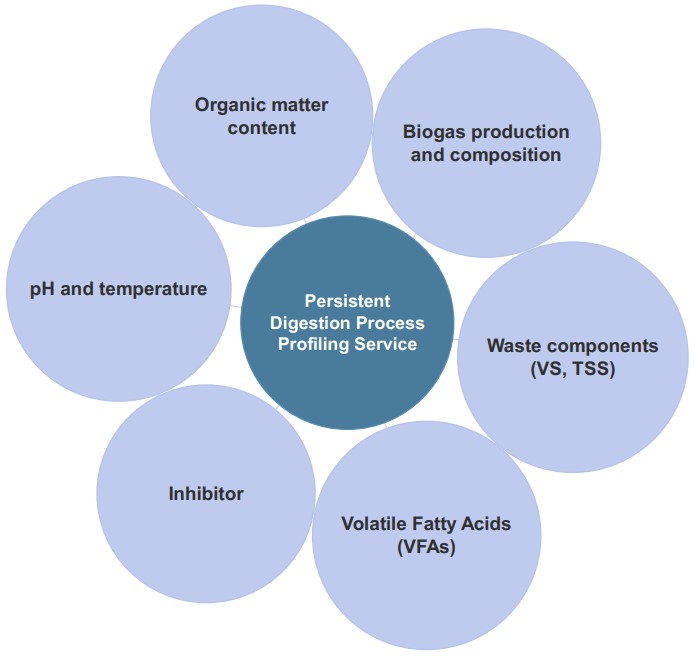

Persistent Digestion Process Profiling Service

Continuous Analysis in Anaerobic Digestion Process at Creative Biolabs

To evaluate the stability, efficiency, and performance of Anaerobic Digestion Systems to improve the efficiency of organic waste treatment and biogas production, continuous anaerobic digestion analysis is often required, which can continuously monitor and evaluate key parameters such as the degradation process of wastewater or waste in anaerobic digestion reactors and the amount and quality of biogas produced, thereby improving the sustainability of the waste treatment process and providing data support for system operation and optimization. Creative Biolabs has strong technical teams with extensive experience in complex biological processes and chemical changes in reactors, who achieve accurate, real-time, and continuous monitoring and analysis of reactor parameters.

When performing continuous anaerobic digestion analysis, sample collection and preprocessing are crucial. Sample collection should be representative and usually requires collecting samples from different locations in the reactor to obtain comprehensive information. We take samples from the anaerobic digestion reactor. The collected samples are then pre-processed, such as solid-liquid separation, filtration to remove impurities, dilution, and other steps.

-

Monitoring and analysis of parameters

We provide monitoring and analysis services on multiple parameters to evaluate digestion reactor performance and stability.

We measure the organic matter content before and after digestion to help clients evaluate digestion efficiency and the amount of biogas produced.

-

Biogas production and composition

We use gas collection systems and flow meters to continuously measure the total production of biogas, the content and proportion of main components (such as Methane, carbon dioxide, etc.), and other gas components to evaluate the quality and production efficiency of biogas.

We provide volatile solids (VS) and total suspended solids (TSS) content analysis services. VS in organic waste is the biodegradable part, and its changes reflect the amount of gas and residues produced during digestion. TSS is used to evaluate the content of solid particles in waste and their removal efficiency during the digestion process.

VFA is an intermediate product in the anaerobic digestion reactor and a key indicator in the anaerobic digestion process. Its concentration changes reflect the activity and stability of microorganisms in the reactor.

Ammonia Nitrogen, as an inhibitor, may affect the stability of the digestive system. We provide concentration monitoring and analysis services for such inhibitors during the continuous digestion process.

pH and temperature are critical to microbial activity and digestion processes, and monitoring their changes helps optimize operating conditions.

The analysis of these parameters helps clients continuously collect data and monitor reactor performance in real-time, thereby helping clients optimize the operation of the continuous anaerobic digestion system and ensure that it converts organic waste into biogas and fertilizer efficiently and stably. Creative Biolabs provides comprehensive integrated solutions for continuous digestion processes, including data monitoring, parameter analysis, and system optimization suggestions, providing clients with a one-stop service. If you are interested in our analysis process, please contact us and we look forward to working with you.

Published data

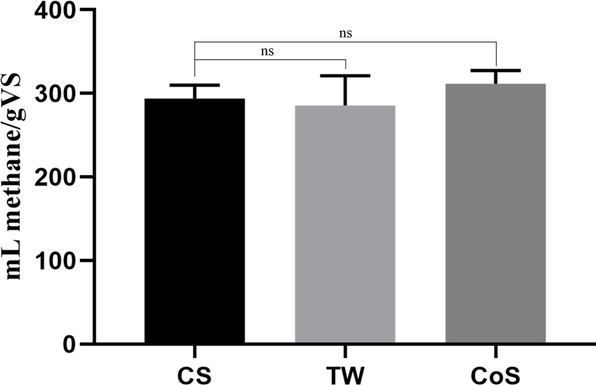

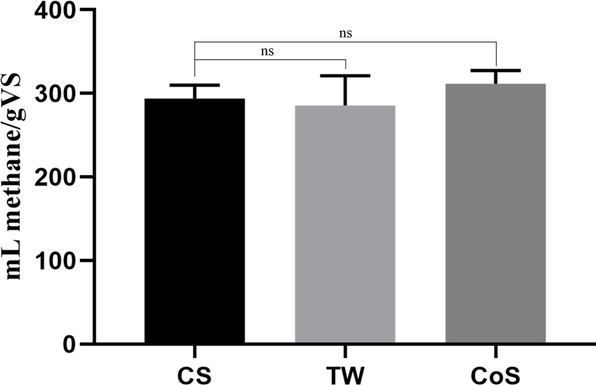

Biogas generated during anaerobic digestion is widely applied in many fields as a renewable energy source. Various biomasses, such as wastewater sludge, corn stover, and agricultural by-products, can be used as substrates for biogas production. Different substrates have a significant impact on the stability and production efficiency of biogas production. Therefore, it is of great significance to study the optimal substrate combination and fermentation conditions. In this study, tomato waste (TW) and corn stover (CS) were selected as research objects to evaluate their biomethane potential (BMP) in batch fermentation and continuous anaerobic digestion processes, and standard analytical techniques were used to monitor the process parameters during the production process. The results showed that TW was a promising biogas substrate that could be used as an effective single substrate in batch fermentation or mixed with corn stover in appropriate proportions to produce biogas in continuous anaerobic digestion. This was because TW has relatively low hemicellulose and lignin contents and its carbon-nitrogen ratio was also lower than that of CS, so it was regarded as a substrate with good biogas production potential.

Fig.1 Biogas yield of biomass in batch fermentation.1, 2

Fig.1 Biogas yield of biomass in batch fermentation.1, 2

FAQs

Q1: Why do we need continuous anaerobic digestion analysis?

A1: Continuous anaerobic digestion analysis helps to understand the degradation process and gas production of biomass waste in bioreactors, helps optimize the process, improves gas production efficiency, and reduces waste treatment costs.

Q2: How do we collect and store samples for analysis?

A2: We provide detailed sample collection guidelines to help you collect samples and ensure proper storage of samples to avoid damage or contamination, thereby ensuring the accuracy of subsequent analysis.

Q3: Can you give specific improvement suggestions or optimization plans according to the analysis results?

A3: Yes, we will formulate targeted improvement suggestions according to the analysis results, including adjusting process parameters, adding auxiliary materials, or improving operating methods, etc., to optimize the continuous anaerobic digestion process.

Customer Review

Custom Anaerobic Digestion Analysis Service

"Client first! From the beginning to the end, the Creative Biolabs team focused on client needs, always paid attention to our feedback and needs, and provided custom analysis solutions. This considerate service attitude impressed us deeply."

Improve Clients' Operational Efficiency Through Professional Digestion Analysis

"Outstanding analysis service! The Creative Biolabs team provided in-depth insights into our continuous anaerobic digestion process, offering practical solutions that significantly improved our operational efficiency."

References

-

Szilágyi, Árpád, et al. "A comparative analysis of biogas production from tomato bio-waste in mesophilic batch and continuous anaerobic digestion systems." PLoS One 16.3 (2021): e0248654.

-

Under Open Access license CC BY 4.0, without modification.

For Research Use Only.

Related Services

Fig.1 Biogas yield of biomass in batch fermentation.1, 2

Fig.1 Biogas yield of biomass in batch fermentation.1, 2